A Cartridge Nut plays a crucial role in various mechanical systems. It is often found in applications like faucets, automotive parts, and even some machinery. Understanding how this essential component works can enhance our appreciation for everyday objects.

The Cartridge Nut typically secures a cartridge within a housing. This design allows for easy replacement and maintenance. You may wonder how often these components need to be replaced. While some may last for years, others degrade much faster due to pressure and temperature changes.

These nuts come in different sizes and materials. Choosing the right one can be challenging. Some may fit perfectly, while others do not. Reflecting on the importance of a Cartridge Nut can lead to better purchasing decisions. Many overlook these small yet significant parts, which can lead to inefficient systems. Recognizing their value is key to maximizing performance.

A cartridge nut is a vital component in many mechanical systems. It plays a crucial role in maintaining the integrity of various assemblies. These nuts are characterized by their ability to hold cartridges securely in place. This function is essential in applications ranging from automotive systems to industrial machinery. Recent industry reports indicate that the global demand for these components is projected to grow significantly, driven by advancements in manufacturing processes.

Cartridge nuts are designed for easy installation and removal. They provide reliable performance under various conditions, including high pressure and temperature fluctuations. A report by the Machinery Research Institute highlights that over 40% of mechanical failures stem from improperly secured components. This statistic underscores the importance of using quality cartridge nuts in assemblies. Despite their advantages, not all cartridge nuts are created equal. Some may struggle under extreme stress, leading to performance issues. Regular inspections are essential to ensure their reliability.

Operators must also consider material selection. The right material can enhance the cartridge nut's durability and resistance to corrosion. Studies indicate that 30% of machinery downtime can result from inadequate component quality. Decisions surrounding these small but significant components can have far-reaching effects. It is critical to reflect on the choices made in sourcing and maintaining cartridge nuts. Proper understanding leads to more efficient operations and reduced costs.

A cartridge nut is an essential component in many mechanical systems, often used in applications like faucets, machinery, and automotive parts. At its core, a cartridge nut holds the cartridge in place, allowing smooth movement and functionality. To understand its role, we must explore its components.

Typically, a cartridge nut consists of several parts. The body serves as the main structure, supporting the internal components. This part is usually made from durable materials such as brass or stainless steel. These materials ensure longevity and resilience against wear and corrosion. Inside the cartridge nut, seals and O-rings provide a tight interface, preventing leaks. Data from industry reports suggest that over 75% of cartridge issues arise from seal failure, highlighting their importance.

Another critical component is the threaded section, enabling the cartridge nut to be securely fastened. This threading must be precise; otherwise, it can lead to installation errors or reduced stability. Interestingly, engineers are constantly seeking ways to enhance the design. Some recent studies indicate that advancements in 3D printing technology could lead to improved cartridge nut designs that optimize performance. Yet, there remains a confusion around material selection, requiring further exploration and testing in real-world scenarios. Failure to address these design concerns can negatively impact overall system efficiency.

| Component | Description | Function |

|---|---|---|

| Nut Body | The main part that houses the other components. | Provides structural support and encloses inner components. |

| Internal Threading | Inside the nut body, allows screws or bolts to be inserted. | Enables secure fastening to other components. |

| Seal | A gasket or o-ring inside the nut. | Prevents leakage and protects against contaminants. |

| Retaining Ring | A circular piece that holds components in place. | Keeps the assembly intact during operation. |

| Guide Pin | Aligns the nut with the mating component. | Ensures proper positioning for assembly. |

Cartridge nuts play a crucial role in mechanical systems. They function by providing a locking mechanism that secures parts together under tension. This is vital in applications ranging from automotive to aerospace industries. A report by the Machinery Institute shows that improper fastening can lead to mechanical failures, costing companies an estimated $25 billion annually in repairs and downtime.

In operation, cartridge nuts utilize an internal thread design that allows for easy installation and removal. This is particularly beneficial in assembly lines, where efficiency is key. The same report indicates that using cartridge nuts can reduce assembly time by up to 30%. However, design flaws or installation errors can compromise their effectiveness. Engineers need to ensure proper torque specifications are met to avoid joint failures.

Moreover, cartridge nuts must withstand a range of environmental factors. Exposure to high temperatures or corrosive elements can degrade their performance over time. A study from the International Journal of Mechanical Engineering highlights that 20% of mechanical failures are attributed to wear and tear on fasteners. This emphasizes the importance of regular maintenance checks. It’s crucial to reflect on best practices when implementing cartridge nuts in mechanical systems.

Cartridge nuts are versatile components utilized across various industries. They are commonly found in automotive manufacturing, where they provide a strong fastening point for critical engine components. In these settings, they help to secure parts under immense stress, ensuring the reliability of the vehicle. The ease of installation makes them essential in assembly lines, though sometimes their replacement can be tricky.

In the construction industry, cartridge nuts are frequently used to fasten heavy machinery or secure structural elements. They improve stability in constructions, but their performance can be affected by environmental factors. For example, corrosion in damp conditions might compromise their strength. This raises questions about proper material choices in different climates, prompting a need for better understanding.

Additionally, cartridge nuts play a role in furniture manufacturing. They offer a hidden fastening solution, contributing to sleek designs. However, the challenge arises in ensuring that they provide enough grip. Weak installations can lead to wobbly furniture, which is far from ideal. As industries adopt new technologies, there is potential for innovation in cartridge nut design and functionality.

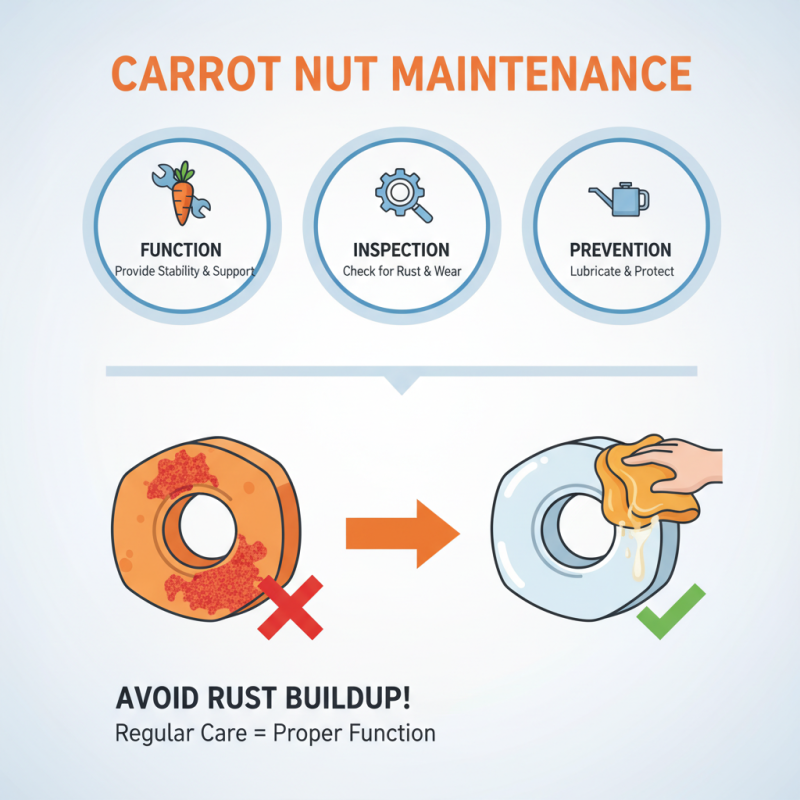

Cartridge nuts are essential components in many applications, providing stability and support. Maintaining these nuts is crucial to ensure they function correctly. One common issue is rust buildup. Rust can make it difficult for the nut to turn or function properly. Regularly inspecting for any signs of corrosion can help catch this problem early.

Another challenge is a loose connection. Over time, vibrations can cause cartridge nuts to loosen. If you notice any movement, it may require tightening. Use the proper tools to avoid damaging the nut. If it feels stuck, applying a suitable lubricant may help. However, be cautious; too much lubricant can attract dirt and debris.

Sometimes, cartridge nuts may start leaking. This often indicates a failure in the sealing. Checking seals regularly can prevent leaks from becoming major issues. Cleaning the area around the nut can also help. It can reveal underlying problems that may need attention. Regular maintenance is not just about fixing problems; it’s about preventing them too.