Choosing the right angle stop valve is essential for plumbing projects. An angle stop valve controls water flow to fixtures. It’s crucial for both new installations and repairs.

When selecting an angle stop valve, consider the material. Options include brass, plastic, and chrome. Each type has its pros and cons. For example, brass is durable but may corrode over time. While plastic is lightweight, it might not withstand high pressure.

You should also think about size and compatibility. An improper fitting can lead to leaks. Leaks can create a costly mess that may require extensive repairs. In some cases, the selected valve may not suit your home’s plumbing system. Therefore, thoughtful consideration is vital. A well-chosen angle stop valve can improve efficiency and minimize future issues.

Angle stop valves are essential components in plumbing systems. They control the water flow to fixtures like sinks and toilets. Understanding their basics helps in making informed choices for your needs.

These valves typically feature a 90-degree angle. This design saves space and simplifies installation. The valve has two main parts: the body and the handle. The handle allows manual control of the water flow. Many users overlook the importance of durability. A strong valve can prevent leaks and prolong the life of your plumbing system.

When choosing an angle stop valve, consider the material. Brass and chrome-plated options are popular for their longevity. However, plastic valves may be cheaper but less durable. Check the size to ensure compatibility. Misjudging the size leads to frustrating leaks and repairs. Be mindful of your specific installation requirements. If in doubt, consult a professional to avoid costly mistakes. Make these considerations to find the best valve for your home.

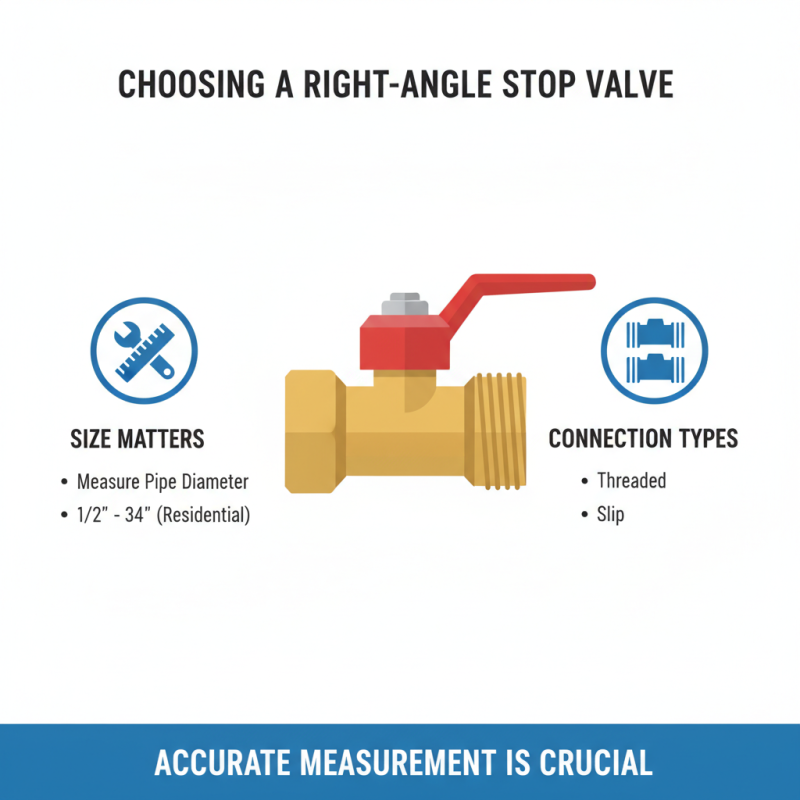

Choosing the right angle stop valve requires a good understanding of your plumbing system needs. Not all valves fit every system. Consider your pipe size and type. For example, residential systems often use 1/2-inch or 3/4-inch pipes. A 2021 report by the American Society of Plumbing Engineers showed that improper sizing accounts for up to 30% of plumbing inefficiencies.

Water pressure and flow rate are critical factors as well. High-pressure systems may require resilient materials, such as brass or stainless steel. Meanwhile, lower pressure might work well with plastic valves. However, plastic can degrade under high temperatures. In fact, studies indicate that 40% of low-cost plastic valves fail within five years in high-temperature conditions.

Also, consider the valve's maintenance needs. Some require periodic checks and replacements. This can add to ongoing costs. A survey indicated that 25% of homeowners overlook maintenance. This leads to leaks and greater repairs down the line. Evaluate your capacity for upkeep before making a choice.

Choosing the right angle stop valve depends heavily on material and durability. Consider how the valve affects your plumbing system. Valves made from brass are known for their strength and corrosion resistance. They can handle high pressure well. However, some lower-quality brass valves may not last long.

Plastic valves are lighter and resistant to rust. They are a good option for less critical applications. But, plastic can degrade under certain conditions. This can lead to leaks. Stainless steel is another durable option. It resists rust and corrosion, ideal for both indoor and outdoor use.

**Tips:** Always check the specifications. Some valves don’t fit all types of plumbing. Look for models that suit your environment. Avoid cheap options if reliability is key. A small mistake in selection can lead to costly repairs later on. Think about long-term use over initial costs. Your choice now can save you headaches down the road.

| Material | Durability Rating | Temperature Resistance (°F) | Corrosion Resistance | Price Range ($) |

|---|---|---|---|---|

| Brass | High | 200 | Moderate | 20 - 50 |

| Stainless Steel | Very High | 300 | High | 50 - 100 |

| PVC | Medium | 140 | Low | 5 - 15 |

| Bronze | High | 250 | Moderate | 30 - 80 |

| Ductile Iron | Very High | 400 | High | 100 - 200 |

Choosing the right angle stop valve involves understanding size and connection types. Size is crucial. A valve that is too large or small can cause issues. Measure the pipe diameter accurately. Most residential applications require valves between 1/2 inch to 3/4 inch. But sometimes, that measurement may not be straightforward. A slip or threaded connection can complicate things.

Connection types matter, too. You may find solder, threaded, or compression fittings. Each has its own advantages. A threaded connection might seem easy, but it needs precise alignment. Solder fittings offer a strong bond, but they require a skillful hand. Compression fittings are great for quick installation, yet sometimes they tend to leak.

If you are unsure, seek advice. Mismatched sizes or connections can lead to water leaks. They may not appear immediately, causing larger problems over time. It’s tempting to rush the decision. However, investing time in understanding your needs leads to better long-term results.

When selecting an angle stop valve, brand reliability and user reviews are crucial. According to a recent report by the Plumbing Manufacturers International, about 40% of consumers cite brand reputation as a top deciding factor. This highlights the importance of choosing a reputable manufacturer. A valve from a reliable brand not only ensures quality but also longevity.

User reviews provide real-world insights. Platforms like home improvement forums showcase varied experiences. Some users report leaks or early failures. Others praise the valve's performance and durability. Pay attention to these stories. They can guide you in making a better choice.

However, not all reviews are created equal. Some may be biased or overly positive. Look for patterns rather than isolated opinions. A valve with numerous positive reviews over time is likely a safe bet. Keep in mind that even well-rated products can still have flaws. Consider your specific plumbing needs when evaluating options.

This chart represents user ratings for various criteria when selecting an angle stop valve. Factors such as durability, ease of installation, cost-effectiveness, performance, and overall user rating are assessed. A higher rating indicates better perceived quality based on user feedback.