Choosing the right angle valve for your plumbing needs in 2025 is a critical decision that can impact the efficiency and functionality of your water distribution system. As technology in plumbing evolves, understanding the various types of angle valves and their specific applications becomes essential for homeowners, plumbers, and contractors alike. An angle valve serves as a control mechanism that directs the flow of water through various appliances, making it a crucial component in ensuring optimal performance in plumbing installations.

In this modern era, where water conservation and sustainability are paramount, selecting the right angle valve not only enhances the overall efficiency of water usage but also contributes to reducing possible leaks and waste. With a wide array of choices available on the market, ranging from traditional brass models to more advanced options featuring smart technology, it is vital to assess your specific needs and the characteristics of each valve type. In the following sections, we will explore key factors to consider when selecting an angle valve, enabling you to make an informed decision that meets your plumbing requirements effectively in 2025.

Angle valves are essential components in plumbing systems, designed to control and regulate the flow of water. They are typically found in areas where pipes change directions, allowing for a more efficient and organized layout of plumbing fixtures. Understanding the basics of angle valves is crucial for homeowners and plumbers alike, as selecting the right valve can significantly impact system performance and longevity.

When choosing an angle valve, it's important to consider the material, size, and application. Common materials include brass and chrome-plated options, which offer durability and resistance to corrosion. The size of the valve should match the piping system to ensure optimal flow and prevent leaks. Additionally, angle valves are available in various types, such as compression and threaded, each suited for different plumbing configurations. By grasping these fundamentals, individuals can make informed decisions tailored to their specific plumbing needs, ensuring an effective and reliable system for years to come.

| Feature | Description | Considerations |

|---|---|---|

| Material | Common materials include brass, plastic, and stainless steel. | Choose based on the environment and pressure conditions. |

| Size | Usually available in 1/2" to 2" diameters. | Select size based on pipe dimensions and flow requirements. |

| Connection Type | Threaded or soldered connections. | Ensure compatibility with existing plumbing. |

| Pressure Rating | Valves rated for different pressure ranges. | Higher ratings for commercial vs. residential use. |

| Valve Type | Options include globe valves, shut-off valves, and more. | Functionality needs dictate valve type selection. |

| Application | Used in residential and commercial plumbing systems. | Identify the specific application for proper selection. |

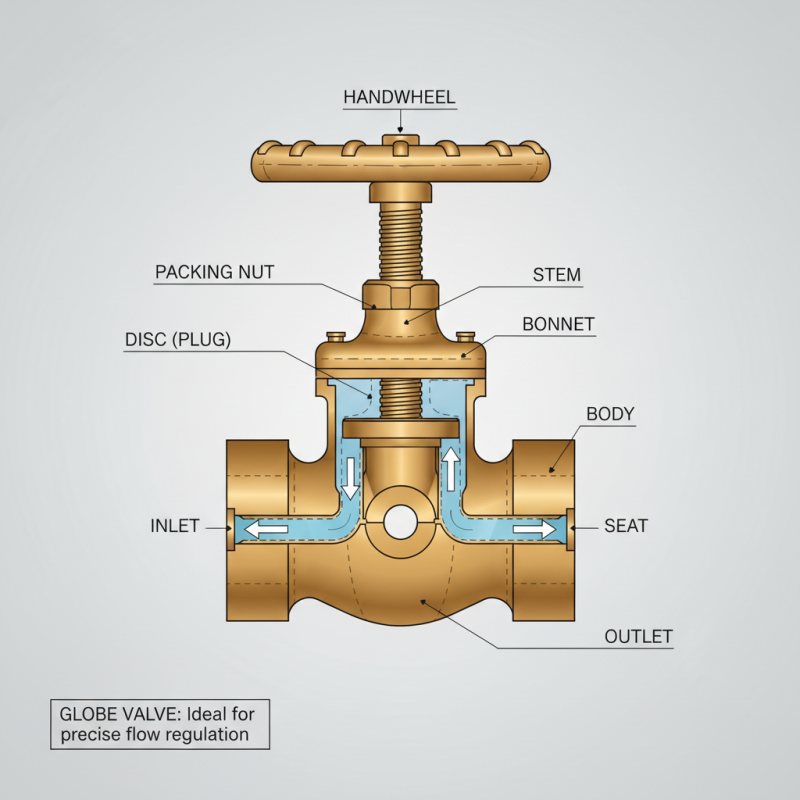

When selecting the right angle valve for your plumbing needs, it's essential to understand the different types available and their specific applications. Common types include globe valves, quarter-turn valves, and ball valves. Globe valves are ideal for regulating flow, as they can be adjusted precisely. Their design allows for smooth control, making them suitable for systems where flow regulation is critical.

Quarter-turn valves, on the other hand, offer a more straightforward mechanism for on/off control. They are popular in residential plumbing due to their ease of use and quick operation. Their design usually features a lever that turns the valve 90 degrees, facilitating a reliable shut-off or release of water flow. Meanwhile, ball valves are known for their durability and minimal pressure drop. With a spherical disc, they provide a tight seal and are excellent for applications requiring quick shut-off capabilities, often found in gas and water supply lines.

Identifying the right angle valve depends on the specific needs of your plumbing project. Understanding the differences among these common types allows homeowners and plumbers alike to make informed decisions, ensuring optimal performance and longevity of the plumbing system.

When selecting an angle valve for plumbing projects, the choice of material is crucial. Brass, for instance, offers exceptional durability and corrosion resistance, making it an ideal choice for both residential and commercial settings. Its ability to withstand high pressures and temperatures makes brass angle valves reliable for various applications. However, they can be more expensive than other materials, which may be a consideration for budget-conscious projects.

On the other hand, PVC angle valves are a cost-effective option with excellent resistance to chemical corrosion, making them suitable for situations where water quality may be a concern. They are lightweight and easy to install, but their temperature tolerance is limited compared to metal options like brass. Conversely, stainless steel valves provide a perfect balance between durability and aesthetic appeal, making them an excellent choice for visible installations. While generally more expensive, their long lifespan and resistance to rust make them worthwhile in the long run. Thus, evaluating these material options according to your specific plumbing needs can significantly impact the performance and longevity of your plumbing system.

When selecting the right angle valve for your plumbing needs, several key factors must be taken into consideration. First and foremost, you should evaluate the materials used in the valve’s construction. Common materials include brass, stainless steel, and PVC, each offering different advantages in terms of durability and compatibility with various types of fluids. For instance, brass valves are robust and suitable for high-pressure systems, while PVC is lightweight and often used in residential plumbing applications.

Another crucial factor is the valve's size and connection type. Ensure the valve matches the diameter of your existing piping system to prevent leaks or pressure loss. Additionally, consider whether you need a threaded or soldered connection, as this affects installation and compatibility with other components. Lastly, check the valve's rating for temperature and pressure to ensure it meets your specific plumbing requirements, particularly if you anticipate fluctuations in water pressure or temperature extremes. By carefully assessing these factors, you can choose an angle valve that optimally fits your plumbing needs.

As we look ahead to 2025, angle valves are expected to undergo significant transformations driven by advancements in technology and design. Future trends suggest a shift towards more sustainable and energy-efficient materials that not only enhance functionality but also align with the growing demand for eco-friendly solutions in the plumbing industry. The integration of smart technology is becoming increasingly prevalent, allowing for remote monitoring and control of plumbing systems, which can optimize water usage and reduce waste.

Moreover, design innovations will likely emphasize aesthetics alongside performance. The classical bulky designs are giving way to sleek, minimalist models that complement modern interiors. Enhanced durability through advanced manufacturing techniques will also be a focus, ensuring that angle valves can withstand extreme conditions and extend their lifespan. These trends reflect a broader move towards integrating technology with traditional plumbing needs, aiming for efficiency, sustainability, and style in the ever-evolving landscape of plumbing solutions.