In a rapidly evolving global market, the demand for high-quality plumbing components such as Angle Stop Valves has surged significantly. According to a recent report by Industry Research, the global Angle Stop Valve market is projected to reach USD 2.5 billion by 2027, with a compound annual growth rate (CAGR) of 4.8% from 2020 to 2027. This growth is propelled by the increasing investments in infrastructure and construction, particularly in developing regions. As a critical component for controlling water supply in residential and commercial plumbing systems, the importance of import-export certifications for Angle Stop Valves cannot be overstated. Ensuring compliance with international standards not only enhances product credibility but also facilitates smoother market entry. As the global trust in "Made in China" products continues to strengthen, maintaining consistent quality across exports is essential for manufacturers aiming to establish a competitive edge in the international arena.

When engaging in the global trade of angle stop valves, understanding the various types of import and export certifications is crucial. These certifications not only ensure compliance with international standards but also enhance the credibility of manufacturers in the competitive market. Key certifications include ISO 9001, which focuses on quality management systems, and the CE mark, which indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

Additionally, certifications like the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) provide specifications that ensure the valves meet performance and safety criteria expected in U.S. markets. Understanding these certifications helps manufacturers develop products that meet the diverse legal and technical requirements of different countries, ultimately facilitating smoother trade transactions and fostering trust with global buyers.

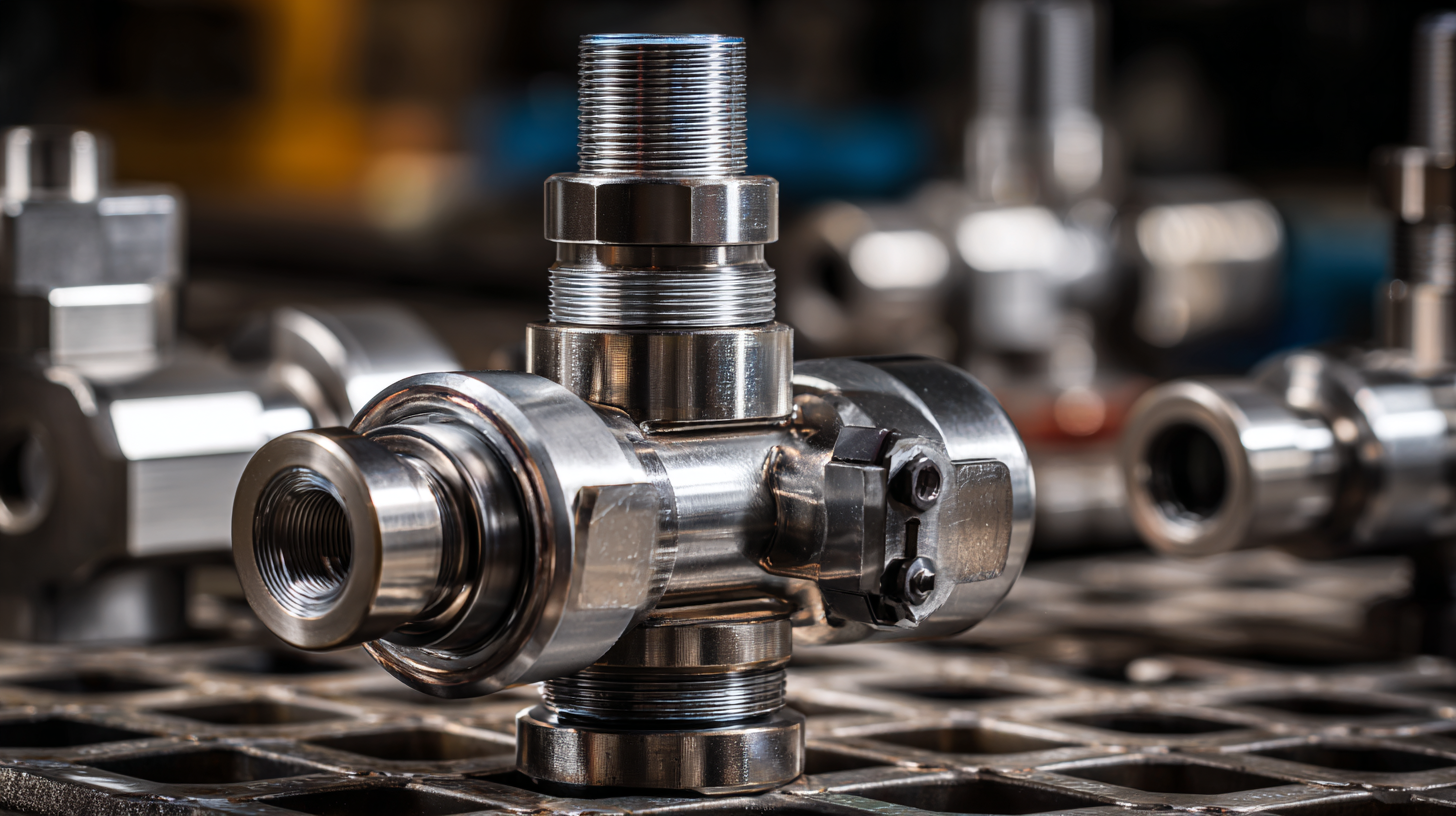

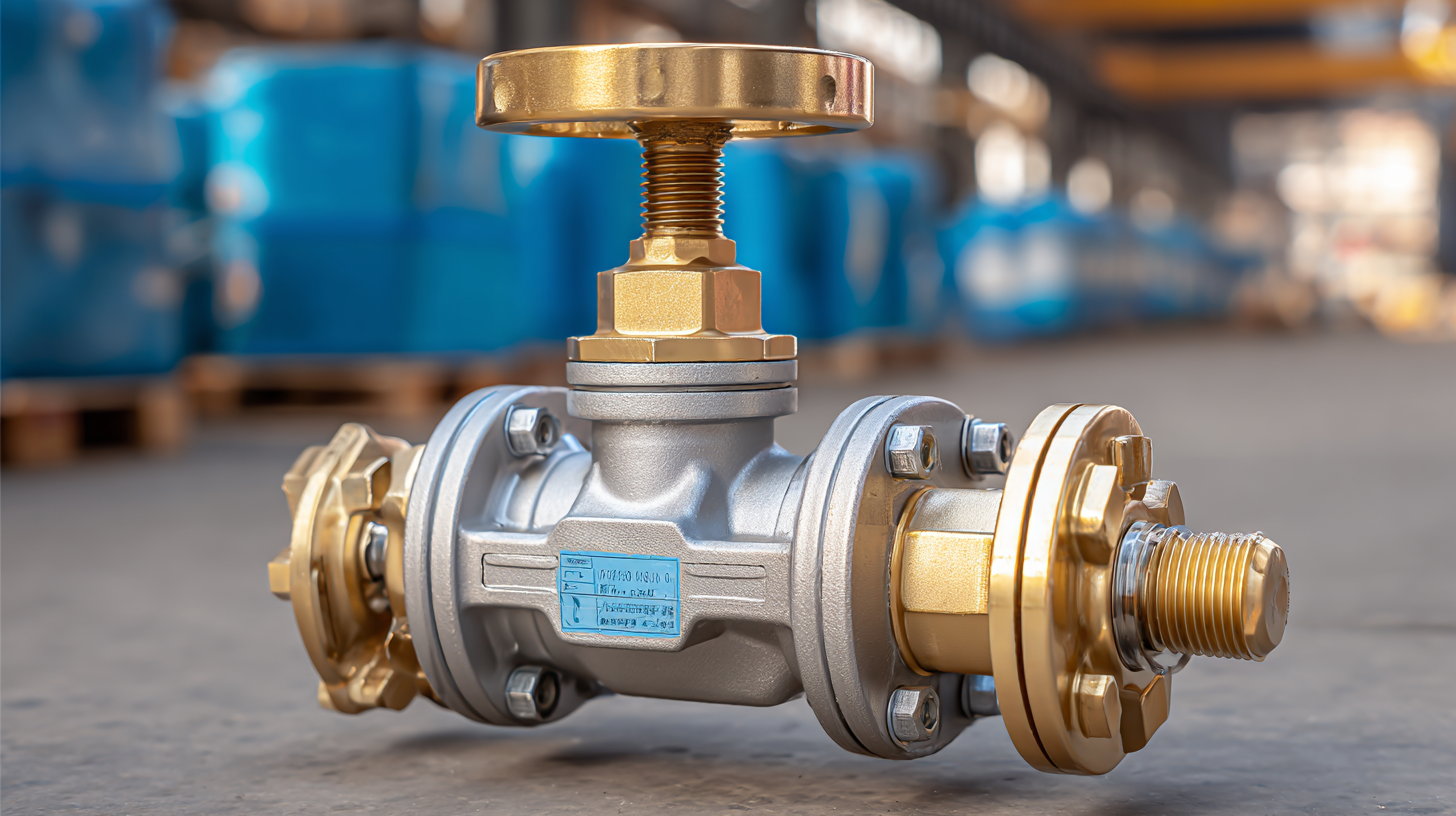

Angle stop valves are essential components in plumbing and piping systems, known for their ability to control the flow of water and other fluids. Designed with a 90-degree angle, these valves allow for efficient space utilization and easy installation. They are commonly used in residential and commercial applications, including bathroom sinks and kitchen faucets. The key features of angle stop valves include their durable construction, corrosion resistance, and ease of maintenance, making them suitable for a variety of environments.

In global markets, the demand for angle stop valves continues to grow due to the increasing focus on efficient plumbing solutions. Their applications extend beyond standard household use; they are also critical in industries such as manufacturing and food processing. With varying sizes and materials available, angle stop valves can be customized to meet specific needs, ensuring adequate support for various fluid types. Understanding these features and their applications is crucial for manufacturers and suppliers looking to cater effectively to the global demand for reliable and efficient valve solutions.

| Feature | Description | Market Applications | Import Export Certification |

|---|---|---|---|

| Material | Brass, Stainless Steel, PVC | Water supply, Industrial piping | ISO 9001, CE Mark |

| Size | 1/2", 3/4", 1" | Residential plumbing, Commercial applications | ANSI Standards, NSF Certification |

| Pressure Rating | 150 PSI, 300 PSI | Heating systems, Air conditioning | UL Certification |

| Functionality | On/Off control, Flow regulation | Irrigation systems, Oil and gas | HACCP Certification |

| Connection Type | Threaded, Soldered, Flanged | Fire protection systems, Wastewater management | ASTM Certification |

Understanding international standards for importing angle stop valves is crucial for manufacturers and suppliers aiming to thrive in the global market. These standards not only ensure the safety and quality of the products but also facilitate smoother trade between nations. Various countries have stringent certification requirements that dictate the materials, manufacturing processes, and testing methods to be adhered to. Compliance with these standards helps in mitigating issues related to product recalls or safety hazards that can arise from substandard imports.

The current trade dynamics, particularly with regards to countries like China, highlight the importance of these certifications. For instance, as international scrutiny of trade practices increases, nations are tightening regulations to protect their local industries and consumer safety. India's recent measures to curb certain imports from China reflect a growing trend where governments prioritize local manufacturing capabilities while enhancing safety standards for imported goods. This environment necessitates that companies dealing in angle stop valves remain vigilant about compliance with international regulations to navigate the complexities of global trade effectively.

In the dynamic landscape of global trade for plumbing products, navigating certification processes is critical for suppliers of angle stop valves. The existing restrictions under the USMCA trade law illustrate the complexities exporters face, even as tariffs lessen. To successfully penetrate markets like Mexico, it's essential for manufacturers to understand specific certification requirements that ensure compliance with local regulations. This is particularly significant in contexts where safety and quality standards are heavily emphasized.

The safety valve market is projected to grow remarkably, soaring from USD 5.2 billion in 2025 to nearly USD 11.87 billion by 2035, demonstrating a robust CAGR of 8.6%. As demand increases, the need for manufacturers to obtain relevant certifications becomes paramount. For example, the emergence of innovative technologies like additive manufacturing has led firms to pursue new certification standards, ensuring their products meet evolving safety and efficiency benchmarks. With the right certifications in place, companies can enhance their competitiveness and embrace the opportunities within the booming global market for valves.

In today's global market, the certification of angle stop valves plays a pivotal role in determining both market competitiveness and consumer trust. Certifications ensure that products meet specific standards for quality, safety, and efficiency, which helps businesses differentiate themselves from competitors. When valves bear reputable certifications, they not only comply with regulations but also signal reliability to potential buyers, fostering a sense of confidence and encouraging purchase decisions.

Tip: When selecting angle stop valves, look for certifications that are recognized in your region or industry. This can enhance the perceived value of the product and ensure that you're investing in quality solutions.

Additionally, certifications can enhance a company's reputation in the marketplace. A certified product can often command higher prices and attract a loyal customer base, ultimately resulting in better profit margins. Companies can leverage these certifications in their marketing strategies to underscore their commitment to quality and trustworthiness.

Tip: Highlighting certification achievements in your promotional materials can help build consumer confidence and expand your market reach. Consider including logos of pertinent certifications on your packaging and advertisements.